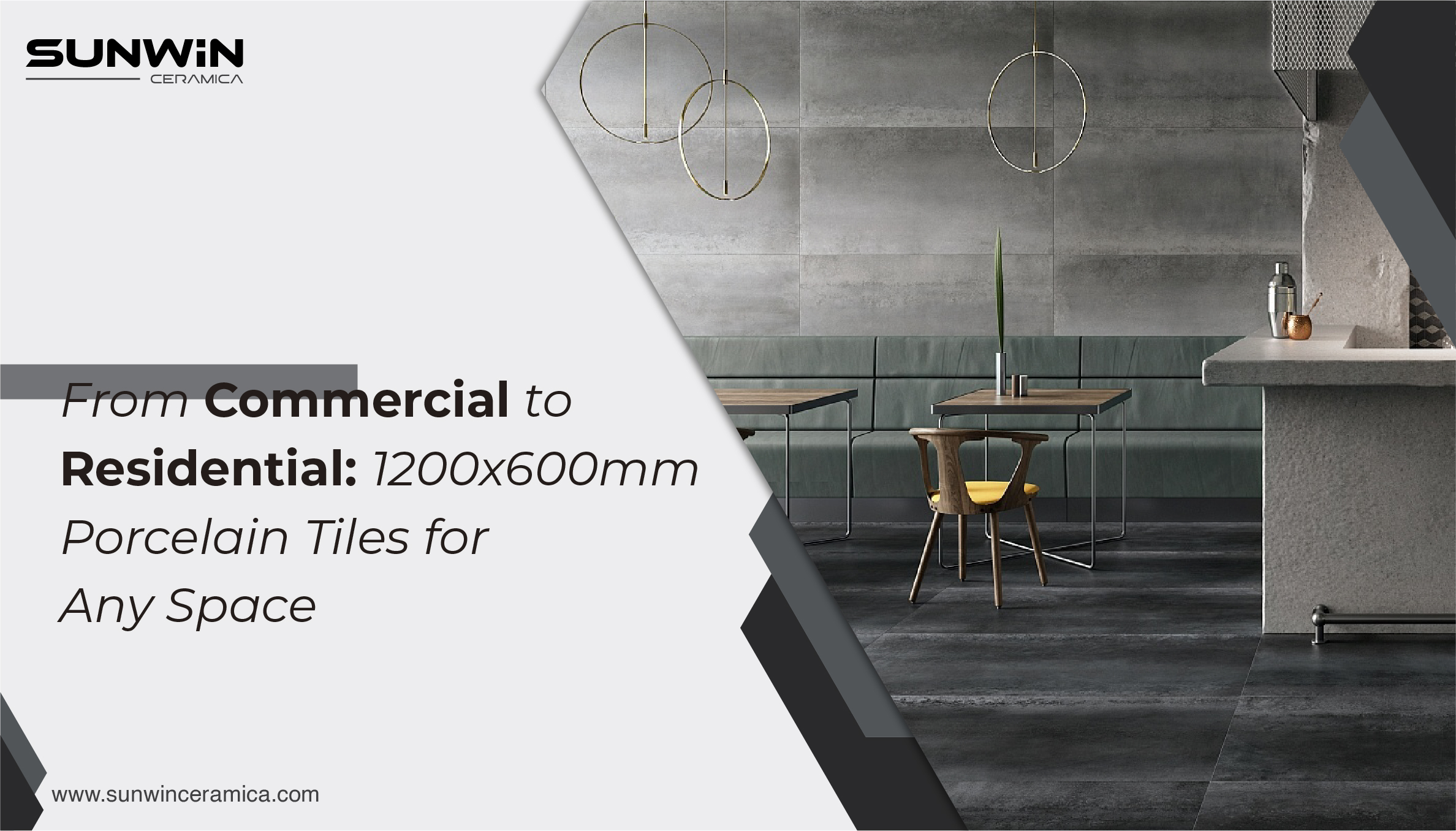

Large format porcelain tiles are now a standard choice in modern construction. They are used in luxury homes. Commercial buildings. Hotels. Retail spaces. Even high-traffic public areas. These tiles create a seamless look. Fewer grout lines. Bigger visual impact.

But here is the reality.

Large-format porcelain tiles are unforgiving if installed incorrectly.

You may have seen tiles that look perfect on day one. Then, after a few months, hollow sounds appear. Edges lift slightly. Corners crack. These issues rarely come from the tile itself. They come from poor installation practices.

This guide explains how manufacturers expect large format porcelain tiles to be installed. Step by step. With technical clarity. So the final result matches the tile’s true potential.

Understanding Large Format Porcelain Tiles

Large format porcelain tiles are generally defined as tiles with one side longer than 600 mm. Common sizes include 600×1200 mm, 800×1600 mm, and slab formats.

Technically, these tiles:

- Have very low water absorption

- Are fired at high temperatures

- Have high density and strength

- Are heavier than standard tiles

Because of these properties, they behave differently during installation. Traditional tile methods are not enough.

Surface Preparation: The Most Critical Step

Surface flatness is the foundation of successful installation. Large tiles cannot bend to follow uneven substrates.

Manufacturer tolerance:

- Maximum deviation of 2 mm over 2 meters

- No sudden height differences

- No loose or dusty surface

Technical preparation steps:

- Check flatness using a straight edge or a laser level

- Grind high spots

- Fill low spots using self-leveling compound

- Ensure the surface is cured and dry

Skipping surface preparation leads to lippage and weak bonding.

Tile Storage and Site Handling

Large format tiles are vulnerable before installation.

Correct handling practices:

- Store tiles vertically, not flat stacked

- Keep them on wooden pallets

- Avoid direct sunlight on the site

- Protect edges with spacers or foam

Improper handling causes micro cracks. These cracks may not be visible immediately but can fail under load.

Choosing the Correct Adhesive System

Large format porcelain tiles require high-performance adhesives.

Technical adhesive requirements:

- Polymer-modified cement-based adhesive

- High initial grab

- Extended open time

- Low shrinkage during curing

Why this matters:

- Porcelain has low absorption

- Larger tiles need stronger bond

- Adhesive must support tile weight

Never use basic tile adhesive for large format tiles. This is one of the most common causes of failure.

Trowel Selection and Adhesive Application

Correct trowel size ensures full adhesive coverage.

Manufacturer recommendations:

- Minimum 10 mm notch for medium formats

- 12 mm or more for very large tiles

- Square-notch or slant-notch trowels

Application technique:

- Apply adhesive in straight lines

- Always trowel in one direction

- Avoid circular patterns

This method allows air to escape when tiles are pressed.

Why back buttering is required for large format tiles

Back buttering means applying a thin adhesive layer on the back of the tile.

Technical purpose:

- Improves adhesive contact

- Eliminates air pockets

- Enhances load distribution

Coverage requirement:

- Walls: Minimum 90% coverage

- Floors: 95% or more

Tiles without back buttering often produce hollow sounds and crack under stress.

Tile Placement and Leveling Systems

Large format tiles must be placed gently and accurately.

Best practices:

- Lower the tile into position

- Do not slide excessively

- Use tile leveling clips and wedges

Leveling systems:

- Reduce lippage

- Maintain an even tile plane

- Hold tiles steady during curing

This is especially important for long rectangular formats.

Joint Width and Movement Allowance

Very tight joints look appealing but create technical risks.

Manufacturer guidance:

- Minimum joint width of 2–3 mm

- Wider joints for outdoor areas

Reasons:

- Tiles expand slightly

- Substrate movement occurs

- Temperature variation exists

Proper joints prevent stress buildup.

Cutting Large Format Porcelain Tiles

Cutting large tiles requires precision tools.

Recommended equipment:

- Professional rail cutters

- Wet saws with porcelain blades

- Waterjet cutting for complex shapes

Technical tips:

- Always support tile fully

- Avoid pressure on edges

- Smooth cut edges with rubbing stone

Poor cutting leads to edge chipping and visible defects.

Grouting and Final Finishing

Grouting locks the installation together.

Use:

- Flexible cementitious grout

- Epoxy grout for wet areas

- Stain-resistant formulations

Grouting steps:

- Clean joints before application

- Do not over-wet grout

- Clean the surface gently

Incorrect grouting damages the tile finish.

Expansion Joints and Structural Movement

Expansion joints are essential in large tiled areas.

Install joints:

- At the room perimeters

- Near columns and walls

- Every 6–8 meters in large spaces

These joints absorb movement and prevent tile tenting.

Curing Time and Post-Installation Care

Tiles need time to settle.

Manufacturer guidelines:

- Light foot traffic after 24 hours

- Heavy load after 72 hours

- Avoid washing for the initial days

Early usage weakens bonding strength.

Common Installation Failures to Avoid

Avoid these frequent mistakes:

- Installing on an uneven substrate

- Skipping back buttering

- Using low-grade adhesive

- Ignoring expansion joints

- Rushing the curing time

Each mistake shortens tile life.

Sunwin’s Recommendation

Large format porcelain tiles deliver premium results only when installed with precision and correct methods. From surface preparation to curing, every step matters.

As a manufacturer supplying large format porcelain tiles to international markets, Sunwin Ceramica follows strict dimensional tolerances and installation compatibility standards to ensure consistent performance on site.

If you are looking for high-quality, large-format porcelain tiles backed by technical guidance, explore the Sunwin Ceramics catalogue. Sunwin Ceramica offers export-grade tiles, consistent quality, and manufacturer support designed for modern construction needs.

Choose the right tile. Install it the right way. Build with confidence.

FAQs

Why do large format tiles sound hollow after installation?

This usually happens due to insufficient adhesive coverage or skipped back buttering, leaving air pockets under the tile.

Can large format porcelain tiles be installed on old tiles?

Yes, large format porcelain tiles can be installed over old tiles only if the existing surface is flat, firmly bonded, and properly primed.

What adhesive is best for large format porcelain tiles?

Polymer-modified, high-performance adhesives designed for large format porcelain tiles provide the strongest bonding and load support.

Are leveling systems mandatory for large tiles?

Tile leveling systems are not mandatory, but they are strongly recommended to control lippage and ensure a flat, even installation.

How long should large format tiles cure before use?

Large format porcelain tiles require at least 24 hours before foot traffic and 72 hours before heavy loads for proper curing.