Large-volume tile imports are never just about numbers. Buyers dealing in bulk always need reliability, uniformity, and long-term performance that leaves an impression. A single inconsistency across the shipments can disrupt the timelines, raise overall rejection rates, and heavily damage customer trust. For importers, contractors, and distributors, consistent quality that matters is much more valuable than competitive pricing.

Ensuring this balance requires more than manufacturing capacity. It calls for controlled processes, experienced teams, and strong quality discipline at every stage of production. This is where dependable tile partners like Sunwin Ceramica make a real difference.

Why Importers Choose Structured Tile Manufacturers for Large Orders?

Bulk tile orders are often shipped across long distances and multiple batches. Without proper controls, variations can appear in:

- Tile size and thickness

- Surface finish and texture

- Shade and colour tone

- Structural strength and durability

Even small deviations can lead to installation issues or client complaints once the tiles reach the site. For importers, this increases replacement costs and risks long-term partnerships.

That is why professional buyers prefer suppliers that prioritise consistency over short-term output.

- Standardised Manufacturing Processes Make the Difference

Consistency starts at the factory level. Large-volume imports require standardised production routines that are followed without shortcuts.

This includes:

- Accurate raw material selection

- Controlled firing temperatures

- Calibrated machinery

- Continuous batch monitoring

When each production stage follows a defined quality benchmark, the final output remains uniform across thousands of square metres. This structure allows bulk orders to be produced with predictable results, even for repeat shipments over time.

- Strong Quality Checks at Every Stage

Quality is not a final step. It is an ongoing process that happens before, during, and after production.

Effective bulk suppliers implement:

- Incoming material inspections

- In-process dimensional checks

- Surface and finish evaluations

- Strength and water absorption testing

These measures helps to identify defects early, thus reducing wastage and shipment delays. For importers, this means that fewer surprises are encountered upon arrival and a smoother on-ground execution.

During long-term partnerships, such systems also ensure that future orders match earlier deliveries closely.

- Managing Shade and Batch Uniformity at Scale

One of the most common problems in bulk tile imports is shade variation. Even minor colour differences can stand out once tiles are installed over large areas.

To avoid this, experienced manufacturers

- Separate production batches clearly

- Use controlled glazing systems

- Maintain detailed batch records

- Supply tiles with consistent shade grouping

This structured handling of batches allows bulk shipments to remain visually uniform, even when orders are spread across multiple containers.

It also helps importers manage inventory better, especially when supplying large commercial or residential projects.

- Capacity Planning Without Compromising Quality

High-volume demand can pressure manufacturing systems. The challenge lies in meeting quantity requirements without diluting quality standards.

Reliable suppliers invest in:

- Scalable production lines

- Skilled technical teams

- Preventive machine maintenance

- Realistic production scheduling

This ensures that large orders are fulfilled within promised timelines while maintaining the same specifications throughout. Buyers benefit from on-time deliveries with consistent product performance.

At this stage, having an experienced partner like Sunwin makes a practical difference, as systems are already designed to handle volume without disruption.

- Packaging, Handling, and Export Readiness

Quality control does not stop once tiles leave the production line. Proper packaging is essential to prevent damage during transit.

Bulk-focused suppliers pay close attention to:

- Export-grade packing materials

- Correct stacking and palletisation

- Moisture and impact protection

- Clear labelling for easy identification

These steps reduce breakage rates and simplify unloading and distribution at the destination port. For importers, this translates into lower loss percentages and smoother logistics.

- Long-Term Benefits for Importers and Distributors

Partnering with a quality-driven manufacturer offers long-term business advantages such as:

- Reduced client complaints

- Better site performance

- Consistency across repeat orders

- Stronger brand credibility in the market

For distributors and project suppliers, uniform tile quality builds trust among contractors, architects, and end users alike. This trust leads to repeat business and easier market expansion.

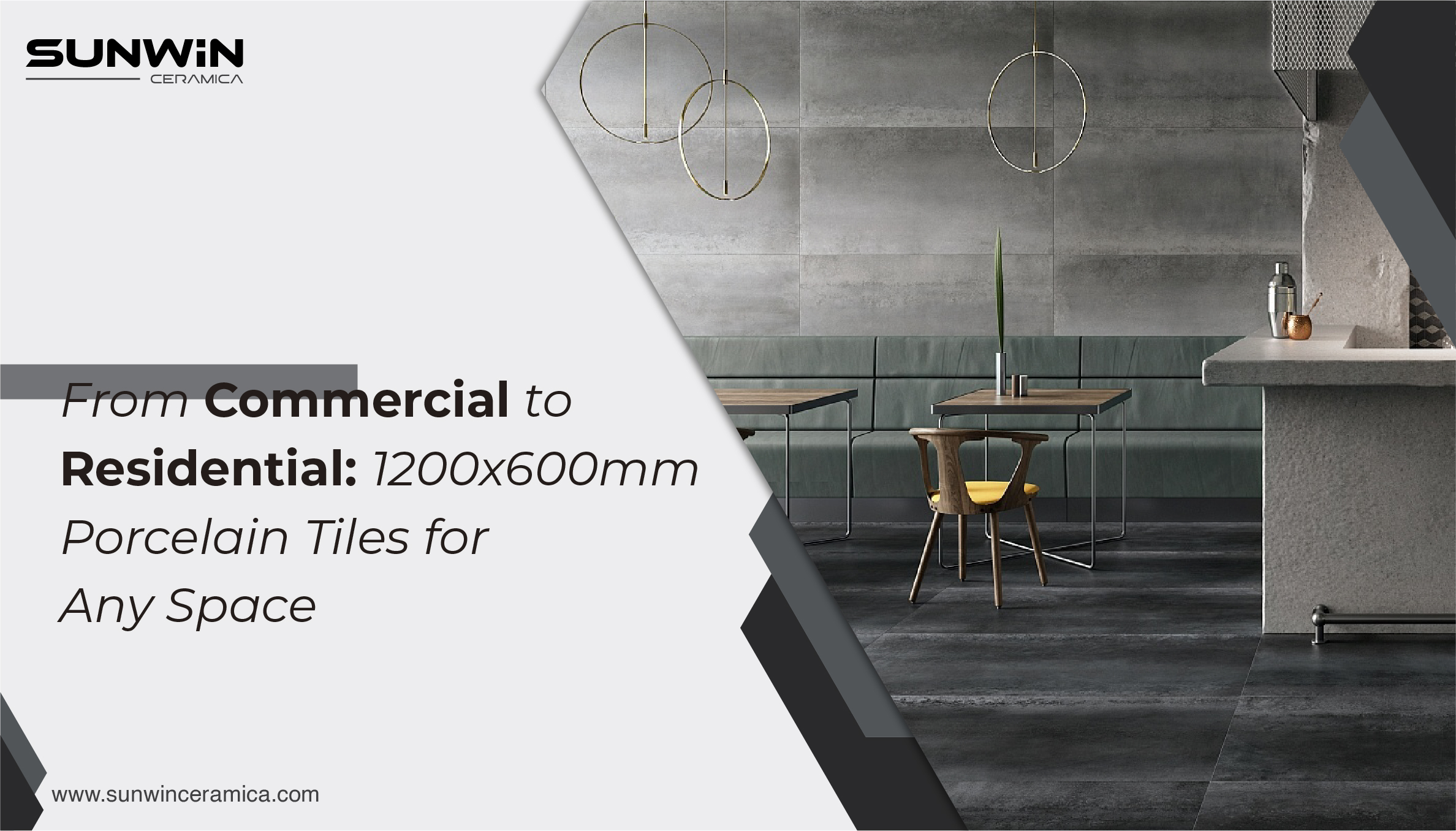

How Sunwin Ceramica Can Actually Make Bulk Quality Feel Simple?

Managing large-volume tile imports becomes easier when quality is controlled from the start. This is where leading and experienced tile manufacturers and exporters like Sunwin Ceramica can step in with a structured, practical approach focused on consistency at scale. The support includes:

- Controlled batch production to maintain uniform shade and finish

- Standardised manufacturing processes for reliable size and thickness

- In-process quality checks to catch issues early

- Export-ready packaging to reduce transit damage

- Repeat-order reliability so future shipments match past orders

Together, these measures help importers reduce risk, avoid delays, and handle bulk tile orders with greater confidence.

Conclusion

Large-volume tile imports demand a balance of scale, structure, and discipline. Consistent quality does not happen by chance. It is the result of controlled processes, experienced oversight, and commitment to long-term standards.

For buyers seeking dependable bulk supply with predictable results, Sunwin Ceramica continues to support large-scale tile imports through structured manufacturing, strict quality checks, and export-ready systems designed for consistency at every level.